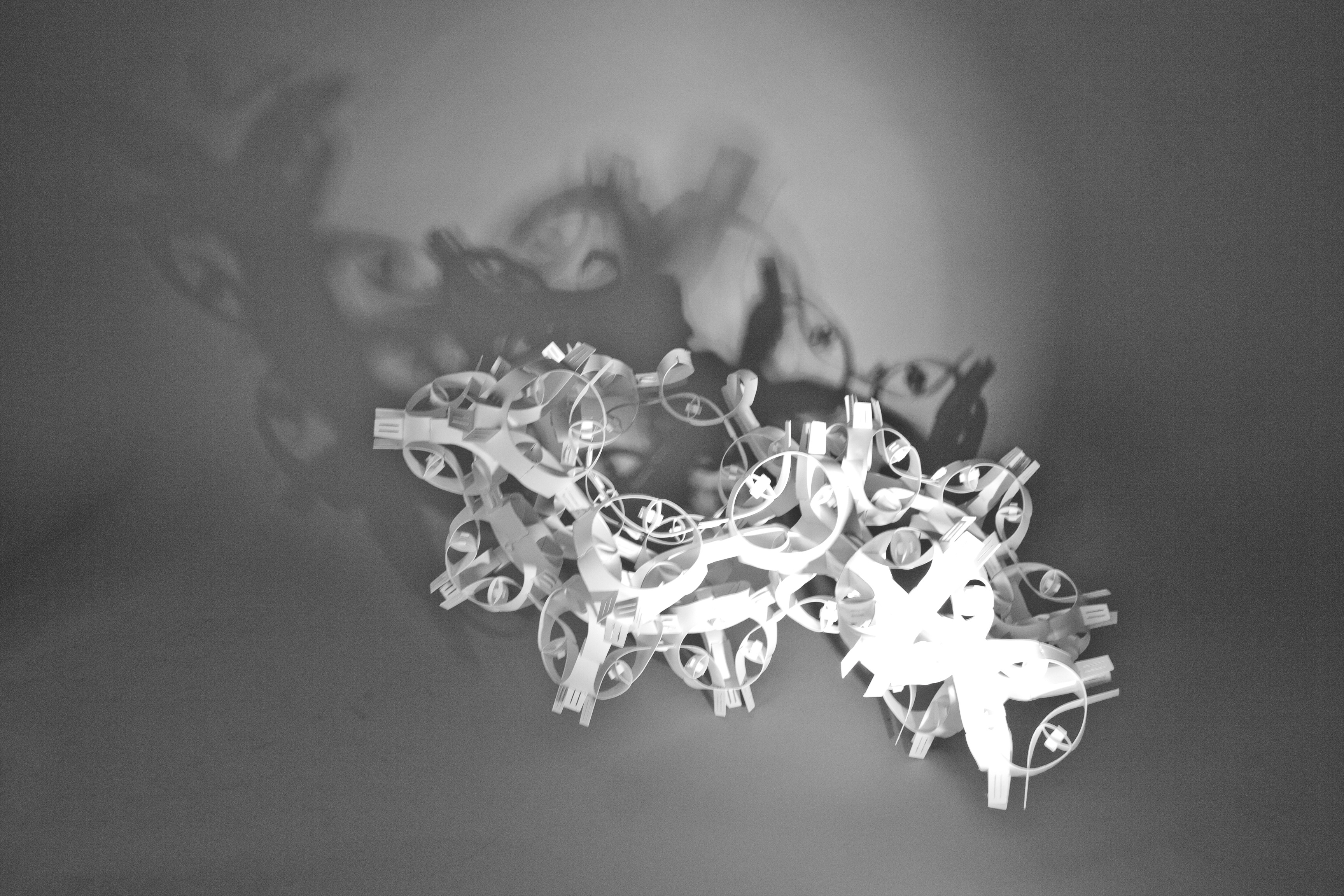

Boot Camp is the very first course of the EmTech program at the AA and consists of exploring a simple geometry as the basis for a complex spatial configuration. The aim is to make a component-based material system derived from the rigorous manipulation of a simple base geometry. It should be self-supported by three ‘anchor points’ in space (floor, wall, ceiling, etc...) and demonstrate a clear hierarchical component logic, resulting in a final form with global curvature, specific orientation and fabrication technique.

![]()

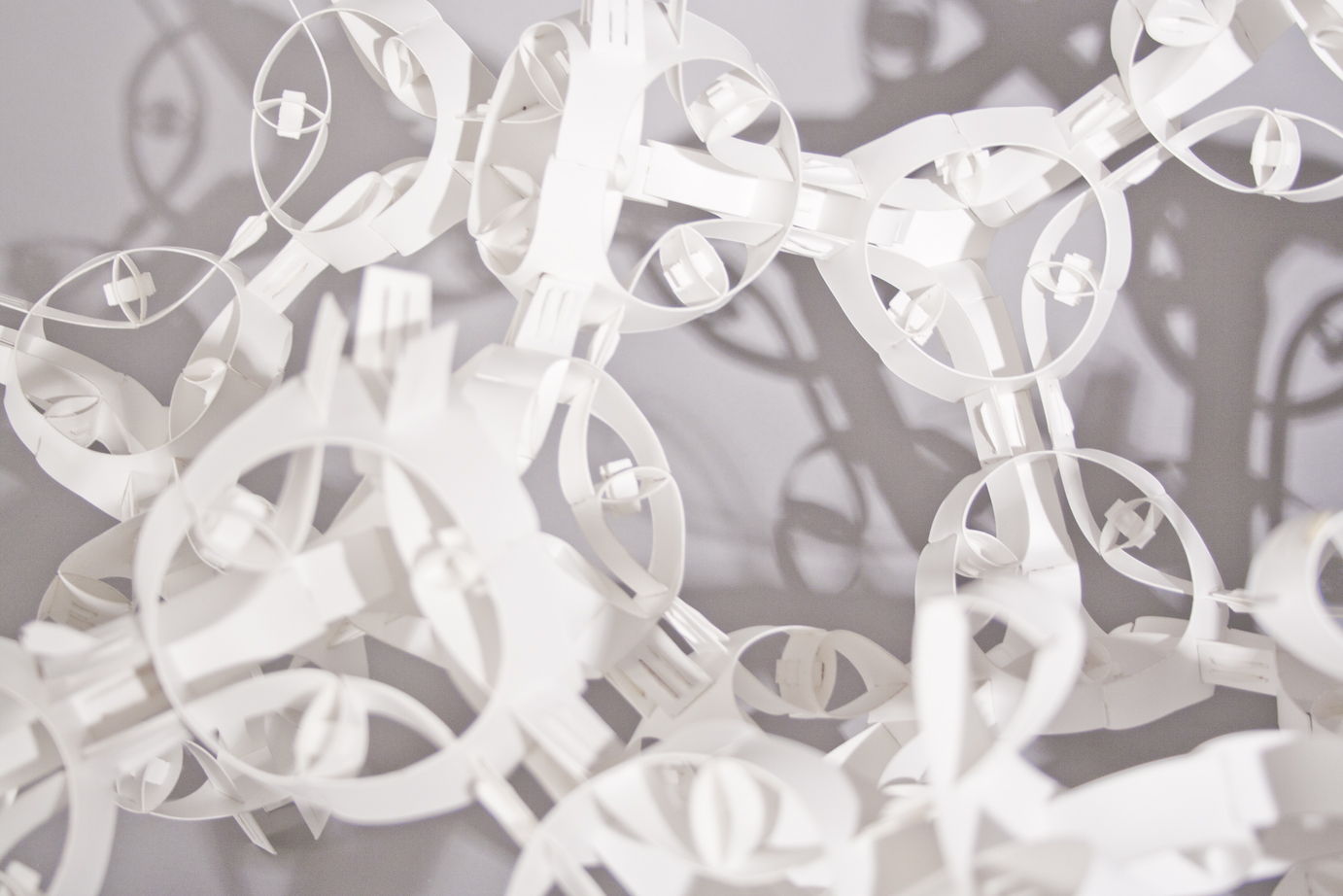

The system is achieved from basic cutouts of paper that are folded and manipulated to assemble and aggregate in large geometrical formations where every single component is inherent in the final pattern. The process comprises the study of the component’s form, the search for proper connections between the modules and the choice of a suitable material that would be consistent with the overall geometry of the system. It is a process where the geometry and design of the single module work hand-in-hand with the physical properties of the material to ensure the stiffness and stability of the system.

The desired outcome for the stiffness of the system results from the folding of the flaps inwards. The system was studied using paper, wood and plastic. Paper allows for a wide range of possibilities for making relatively stiff volumes and surfaces while minimizing the actual mass of the object. It also harbours a lot of friction and allows for major deformations such as buckling, bending and folding. Paper is easy to manage and could be used on small scale. However, it is a very thin material that does not resist any compression and rips under when subject to tension.

The component system actually needed a thicker material and a more elastic one, a material that would slightly resist the bending of the flaps, such as polypropylene. The only advantage that paper has over plastic is its roughness. While the plastic flaps tend to slide out from the slit, the ones made with paper stay stable once inserted into the slits. This unstable and slippery behaviour of the polypropylene requires it to have notches for the flaps to be locked once inserted into the slit. This way, the model would hold mechanically into its position instead of using friction to remain stable.

Each component in the system can connect to a maximum of four others and five of them could be assembled to make a closed loop. Each loop forms a pentagon and the pentagon shape constitutes the next level in the hierarchy before moving towards the shape of a dodecahedron. The used material allows the equal distribution of stresses across the component once it is connected in the system.

Architectural Association

Emergent Technologies & DesignBoot Camp

2011